Zinc Phosphate

Zinc Phosphate is a nontoxic and harmless white antirust pigment which we export, supply and import for our esteemed clients. It is used in corrosion resisting primers, undercoats and in various coating materials for preparing waterproof, acid-resistant or corrosion preventive coating material such as phenolic paint, epoxy paint, acrylic paint, and paste paint.

Specifications:

| Parameters | Nominal Value | Tolerance (±) | Test Method |

|---|---|---|---|

| Average particle size (Microns) M2/gm | 4.5 | – | Laser Granular |

| Bonded Water Content | 15.7 | – | 1 hr at 600 gravimetric |

| Sieve Residue % (on 300 mesh) | 0.5 | Max. | IS 10897:1984 |

Chemical Properties:

| Parameters | Nominal Value | Tolerance (±) | Test Method |

|---|---|---|---|

| Zinc Content % (as Zn) | 50.0 | 2.0 | IS 10897:1984 |

| PO₄ Content % (after Calcinations) | 48.0 | 2.0 | IS 10897:1984 |

| Oil Absorption (CM3/100 gm) | 27.0 | 5.0 | IS 10897:1984 |

| PH | 6.5 | 1.0 | IS 10897:1984 |

Zinc Phosphate – Lab Tested for Quality:

Testing Details:

1. Salt Spray (UDCT) – Has been conducted at UDCT.

2. Bulk density, Moisture, Particle Size (sieve residue), Physical Appearance, oil absorption, PH, conductivity (in house study – By Chemical Analysis) – comparative sheet has been formed for all the parameters listed.

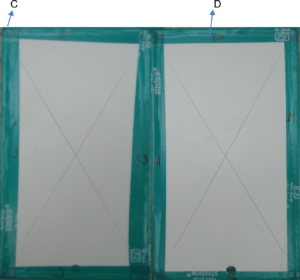

Steps involved in the trials:

- Samples of Zinc Phosphate – 2 Lots C & D from Galaxy International

- Paint Preparation (Epoxy based): Prepared at Reliable Paints (ASTM B 117)

- Panel (M.S) Preparation: Prepared

- Salt Spray: Conducted at UDCT (Based on Honda specification)

Remark:

From the photographs it is clearly seen that the Panel C & D has No Blistering, Popping and Corrosion Penetrations.